Langsam geht es weiter 😉

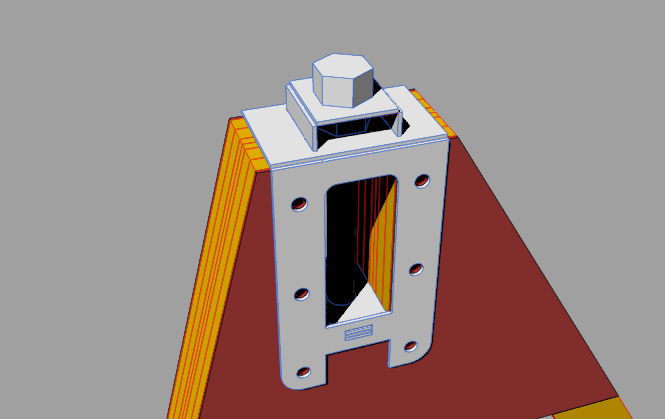

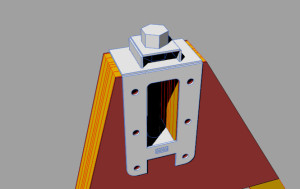

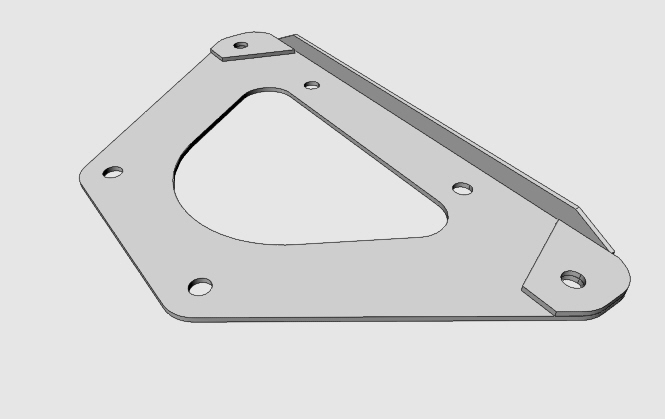

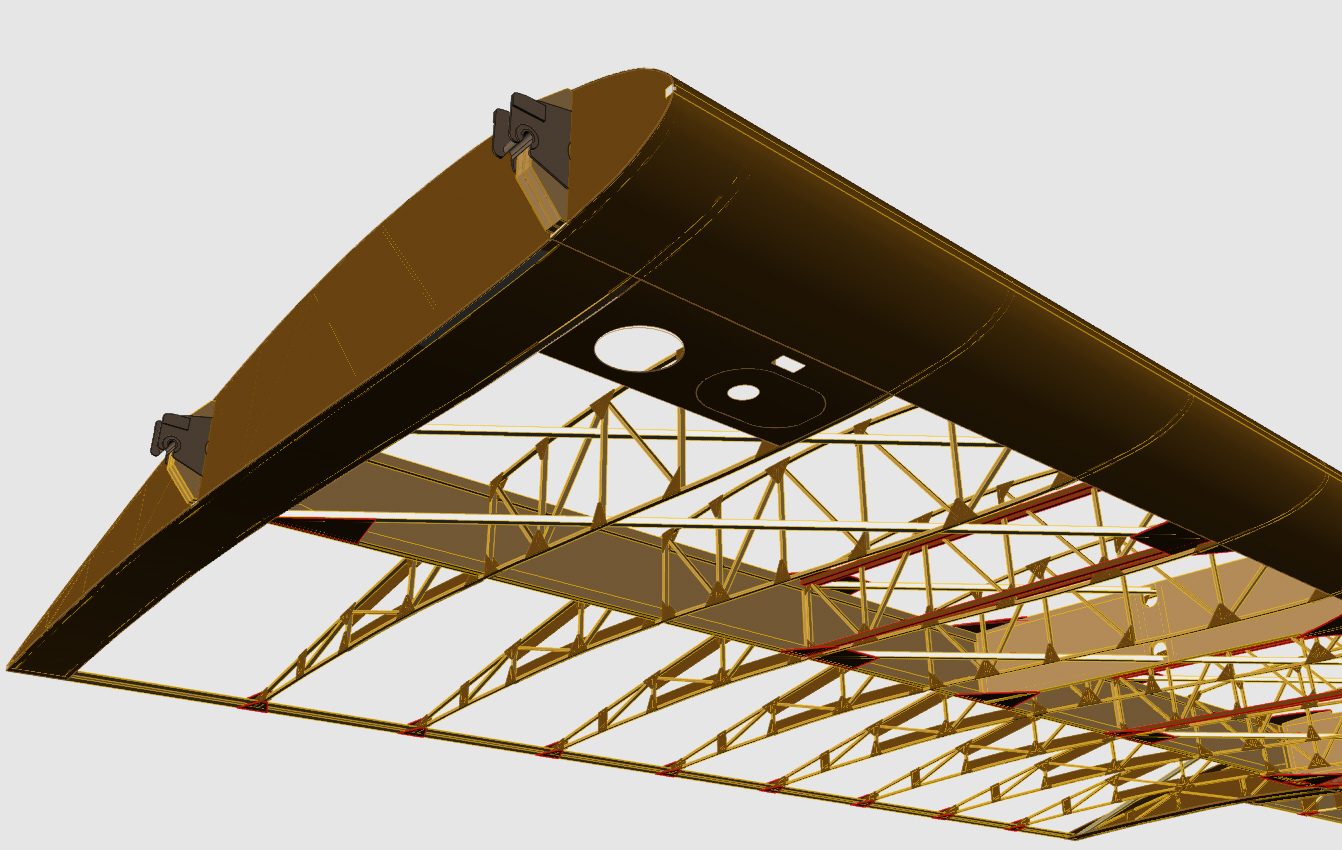

Dieses Mal war die Spannschraube des Spannturms dran. Mit dieser werden die Spanndrähte der Tragflächen gespannt und der Flieger erhält seine eigentliche Festigkeit. Hier musste zunächst eine passende Schraube gefunden werden, da M1-Schrauben nur in begrenzter Länge verfügbar sind. Um diese Schraube wurde dann der Hauptbeschlag drumherum konstruiert. Dabei bin ich leicht vom Vorbild abgewichen, damit dieser hinterher auch funktionsfähig ist.