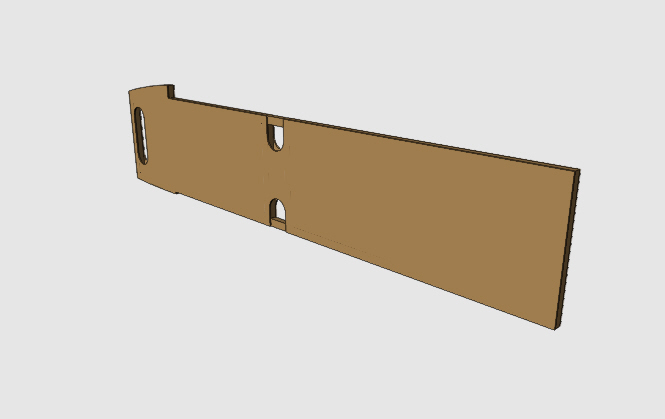

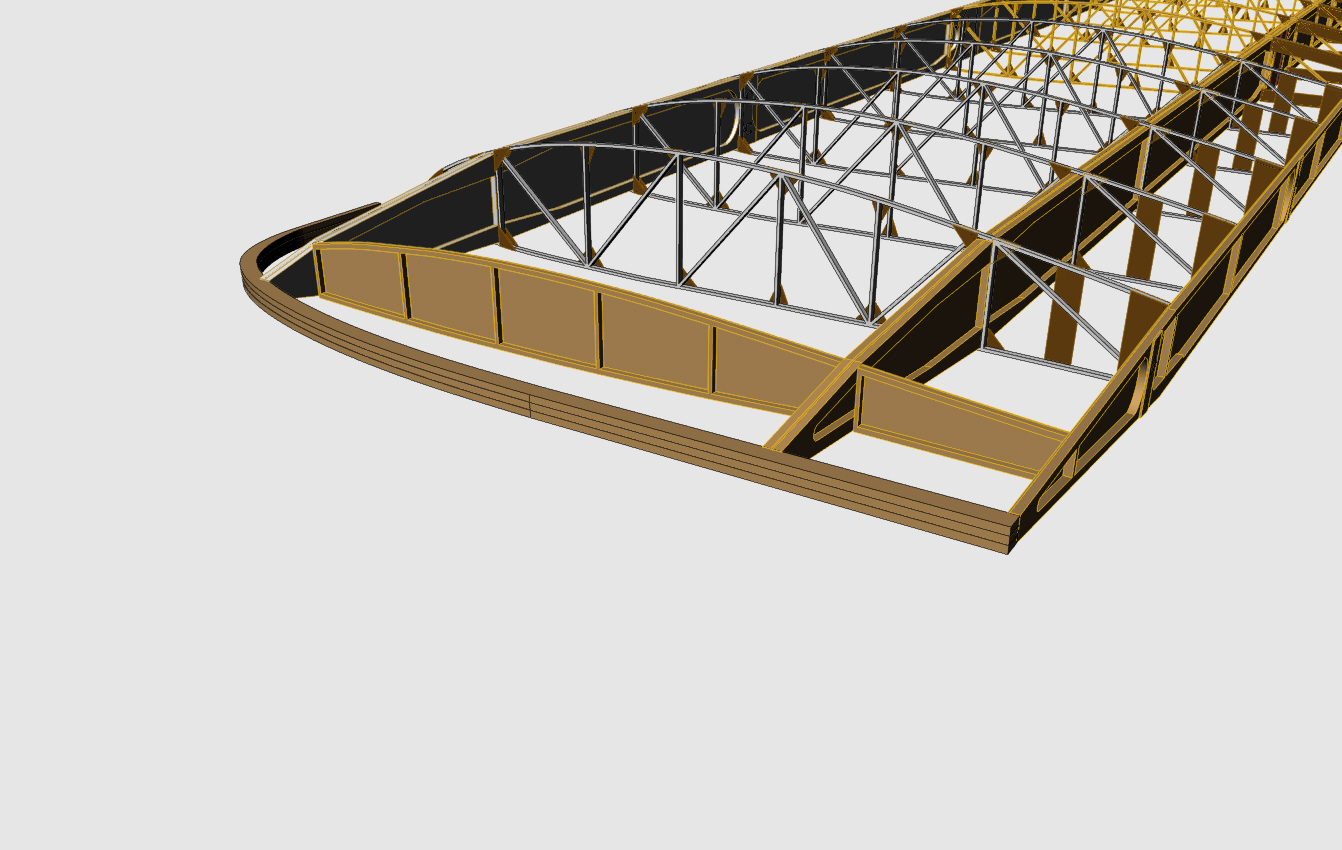

Having finished the corner bracings I moved on to the planking. This was pretty straight forward. I included an offset of 0.1mm as I am planning to use 160gr/m² cardboard for this. My experience for these parts is that the neutral fibre is roughly in the middle for the larger curvatures. Thickness for this material is about 0.2mm. For the root rib I could have used an 0.2mm offset. However ther difference is marginal and the final piece will need a little bit of trimming anyway.

Designing with fully coloured cardboard in mind gives new perspectives. I don’t have to pay that much attention to details. Parts like the planking can be designed a bit larger and then trimmed afterwards. Howver I am aiming to get it perfect 🙂